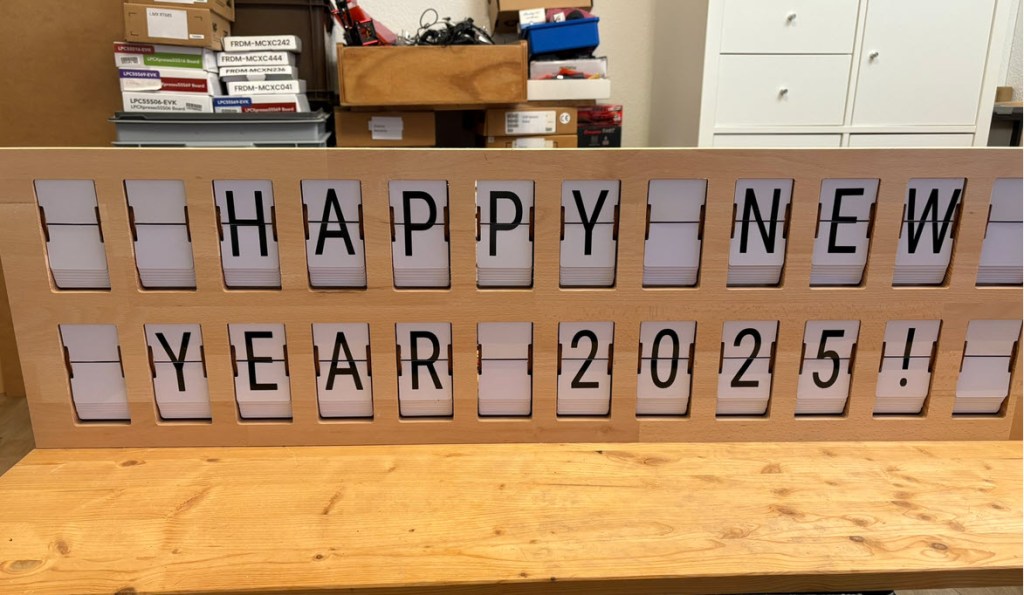

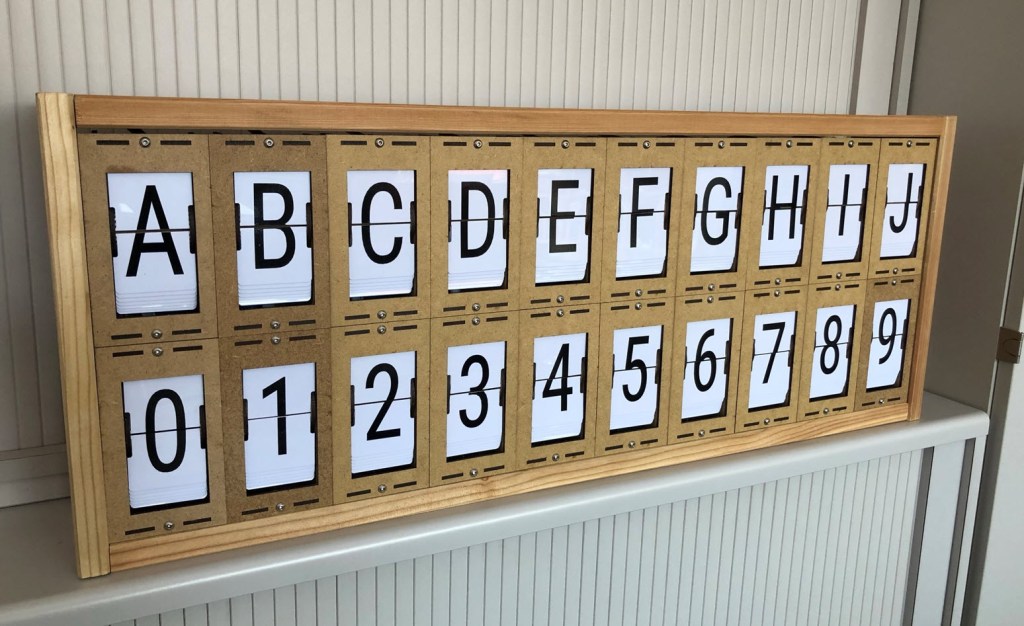

I’m making progress on my larger split-flap project (see Update on the Split-Flap Project for 2025). So far I have 32 operational for the larger 64 flap installation. In parallel, I worked on a smaller 4 flaps unit used as a clock.

I’m making progress on my larger split-flap project (see Update on the Split-Flap Project for 2025). So far I have 32 operational for the larger 64 flap installation. In parallel, I worked on a smaller 4 flaps unit used as a clock.

Sometimes projects need more than a year from start to finish. And this project is even not finished yet. So here is a quick update of the enlarged Split-Flap project for 2025:

Split-flap displays are electromechanical display devices, which were common in airports or railway stations a few years ago.Unfortunately, most of them are gone and replaced by LED displays. Why not create a DIY version of it?

G-Code (or RS-274) is a widely used protocol for CNC machines. I have added vinyl cutting capabilities to the Shapeoko desktop CNC recently (see DIY Vinyl Cutting Drag Knife for Desktop CNC), however cutting vinyl with a drag knife is whole different story compared cutting materials like wood or aluminum. As with many other things, it is about handling all corner cases properly.

A desktop CNC is a great addition to any 3D printer or laser cutter. I consider them ‘the trinity’ for any maker garage. While a desktop CNC is great for wood and some metals like aluminum or brass, it would be great to extend the infrastructure with something more: vinyl cutting. And with this the idea to have cool sticker on my laptop lid: