Bootloaders are a very useful thing: it allows programming an application file without a debugger. This makes it ideal for upgrading a system in the field.

Usually, there are application notes and examples from silicon vendors available. But typically they are for a certain microcontroller, and hard to change it to another system without a lot knowledge about its implementation. What I need for a project based on the FRDM-KL25Z is a bootloader which shall be small and portable. As I’m using Processor Expert to keep my applications portable across different microcontroller families: why not create a bootloader with Processor Expert components? With the Processor Expert drivers available, things can get a lot simpler compared to the ‘traditional’ approach. With less than 10 KByte footprint?

A bootloader is a program which is able to load another program (the application program). Typically the bootloader program is not changed, and is kept in the microcontroller. That way the bootloader can load again and again a different program.

💡 Architecturally there can be a ‘mini’ or ‘micro’ bootloader which can load the ‘real’ bootloader. E.g. the OpenSDA bootloader on the Freedom boards have this capability.

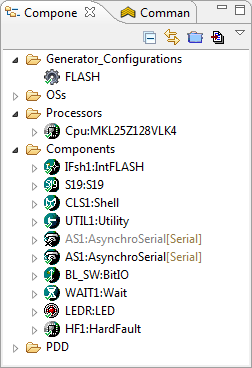

The Bootloader Code and the Bootloader Vectors are programmed into a new part (e.g. with a debugger or a standalone flash programmer (e.g. with USBDM). Then the Bootloader can be used to load or change the Application Code and Application Vectors. With this, the Bootloader remains the same, while the Application can be updated.

Bootloader Sequence

A typical bootloader is doing something like this

- The bootloader decides at startup if it should enter bootloader mode or if it shall run the application. Typically this is decided with a button or jumper set (or removed). If it shall run the application, the bootloader calls the application and we are done :-).

- Otherwise, the bootloader will reprogram the application with a new file. S19 (S-Record) files are often used for this, as they are easy to parse and every tool chain can produce them.

- The bootloader needs to use a communication channel to read that file. That can be RS-232, USB or an SD card file system (e.g. FatFS).

- Using that file, the bootloader programs the flash memory. Special consideration has to be taken into account for the application vector table. As the bootloader runs out of reset, it is using its own (default) vector table, and needs to relocate the vector table if running the application.

💡 It would be possible to use the reset button on the FRDM-KL25Z board as a user button (see this post). To keep things simple, I’m using a dedicated bootloader push button on PTB8.

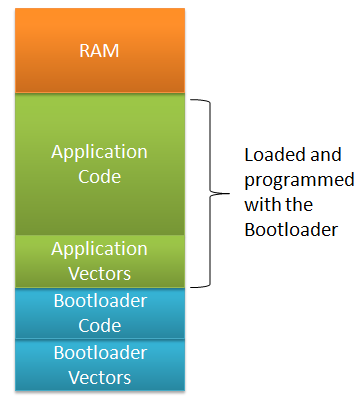

So writing a bootloader requires the following parts:

- Communication Channel: File I/O or any other means to read the Application File.

- File Reader: A reader which reads the Application File.

- Flash Programming: to program the Application.

- Vector Redirection: To switch between the Bootloader and Application Vector Table.

- User Interface: Showing status and information to the user, and to switch between application and bootloader mode at system startup.

Processor Expert comes with Flash Programming and Communication components (USB, SCI, I2C, …) installed. I have a Shell user interface already, plus an S19 file reader component created. Combining this with my other components should enable me to make a bootloader :-).

Flash Memory of the Bootloader

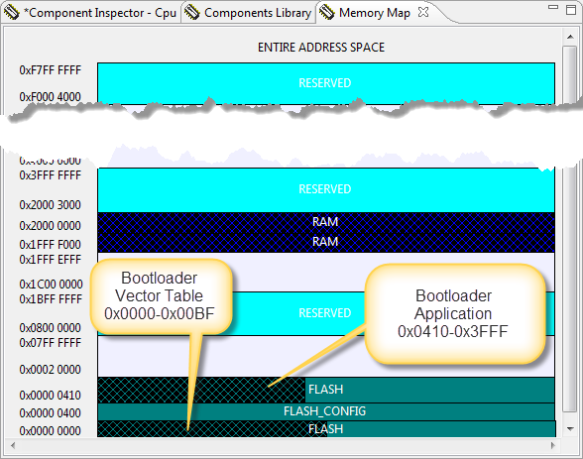

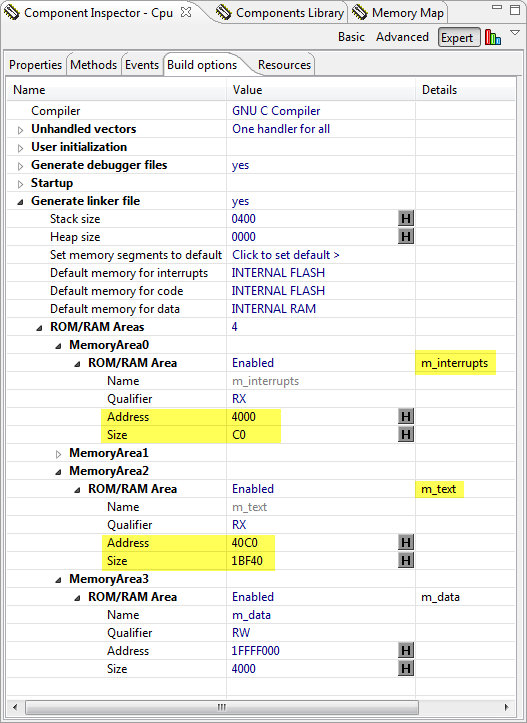

To make sure the bootloader gets linked only into its space, I reduce the FLASH memory for it. With the settings below I limit the FLASH memory from 0x0000 (vector table) up to 0x3FFF. That means my application memory area starts at 0x4000.

So I change the available flash for the bootloader in the CPU properties, and cut the available FLASH size on the KL25Z128 from 0x1FBF0 (~128 KByte) in the Build Options tab to 0x3FB0:

With this, the bootloader occupies the space from address 0x0000 (vector table) up to 0x3FFF.

Flash Protection

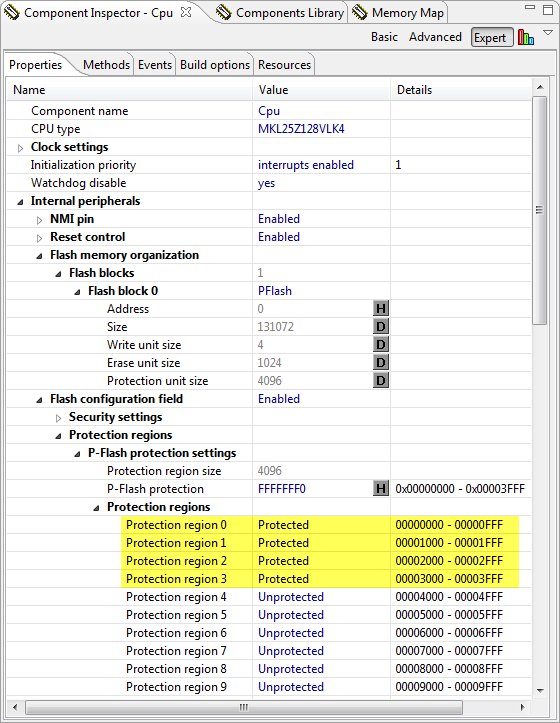

My bootloader resides in the first lower flash pages. To avoid that it might get destroyed and overwritten by the application, I protect the bootloader flash blocks. There is a setting in the CPU component properties where I can protect 4 KByte regions:

Terminal Program

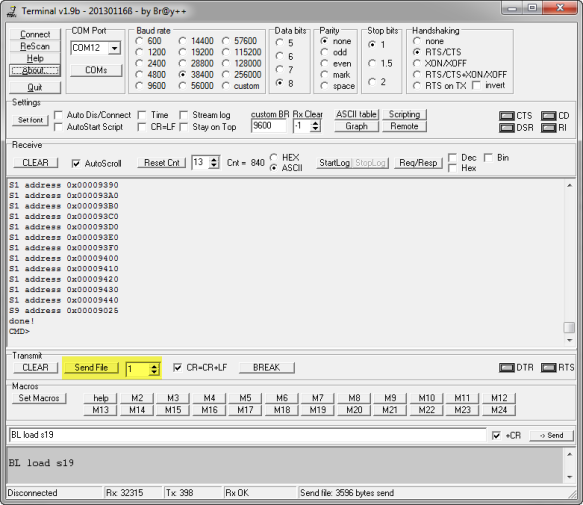

For my bootloader I need a way to send a file with a terminal program. As my serial connection has only Tx and Rx, but no RTS/CTC lines for flow control, it is useful if the terminal program either implements software flow control (XON/XOFF), or a delay value for sending a file.

After some searching the internet, I have found an open source terminal program which exactly can do this: https://sites.google.com/site/terminalbpp/

It supports sending a file with a delay (shown above with 1 ms delay), and supports XON and XOFF. I used it successfully with my bootloader.

💡 Using a zero delay did not work in all cases. Not yet sure why. What worked was sending a file with a 1 ms delay setting.

Bootloader Shell

The bootloader features a shell with following commands:

-------------------------------------------------------------- FRDM Shell Bootloader -------------------------------------------------------------- CLS1 ; Group of CLS1 commands help|status ; Print help or status information BL ; Group of Bootloader commands help|status ; Print help or status information erase ; Erase application flash blocks restart ; Restart application with jump to reset vector load s19 ; Load S19 file

The ‘BL status’ command shows the application flash range, and the content of the application vector table (more about this later):

App Flash : 0x00004000..0x0001FFFF @0x00004000: 0xFFFFFFFF 0xFFFFFFFF

With ‘BL restart’ it starts the user application (if any), and with ‘BL erase’ the application flash can be erased:

CMD> Erasing application flash blocks...done!

Bootloading an Application

With ‘BL load s19’ a new application file can be loaded. It will first erase the application flash blocks, and then waits for the S19. To send the file, I use the ‘Send File’ button:

It writes then the address of each S19 line programmed to the shell console:

CMD> Erasing application flash blocks...done! Waiting for the S19 file... S0 address 0x00000000 S1 address 0x00008000 S1 address 0x00008010 ... S1 address 0x00009420 S1 address 0x00009430 S1 address 0x00009440 S9 address 0x00009025 done! CMD>

Bootloader Details

If I enter ‘BL Load S19’, it executes the function BL_LoadS19() in Bootloader.c:

static uint8_t BL_LoadS19(CLS1_ConstStdIOType *io) {

unsigned char buf[16];

uint8_t res = ERR_OK;

/* first, erase flash */

if (BL_EraseAppFlash(io)!=ERR_OK) {

return ERR_FAILED;

}

/* load S19 file */

CLS1_SendStr((unsigned char*)"Waiting for the S19 file...", io->stdOut);

parserInfo.GetCharIterator = GetChar;

parserInfo.voidP = (void*)io;

parserInfo.S19Flash = BL_onS19Flash;

parserInfo.status = S19_FILE_STATUS_NOT_STARTED;

parserInfo.currType = 0;

parserInfo.currAddress = 0;

parserInfo.codeSize = 0;

parserInfo.codeBuf = codeBuf;

parserInfo.codeBufSize = sizeof(codeBuf);

while (AS1_GetCharsInRxBuf()>0) { /* clear any pending characters in rx buffer */

AS1_ClearRxBuf();

WAIT1_Waitms(100);

}

do {

if (S19_ParseLine(&parserInfo)!=ERR_OK) {

CLS1_SendStr((unsigned char*)"ERROR!\r\nFailed at address 0x", io->stdErr);

buf[0] = '\0';

UTIL1_strcatNum32Hex(buf, sizeof(buf), parserInfo.currAddress);

CLS1_SendStr(buf, io->stdErr);

CLS1_SendStr((unsigned char*)"\r\n", io->stdErr);

res = ERR_FAILED;

break;

} else {

CLS1_SendStr((unsigned char*)"\r\nS", io->stdOut);

buf[0] = parserInfo.currType;

buf[1] = '\0';

CLS1_SendStr(buf, io->stdOut);

CLS1_SendStr((unsigned char*)" address 0x", io->stdOut);

buf[0] = '\0';

UTIL1_strcatNum32Hex(buf, sizeof(buf), parserInfo.currAddress);

CLS1_SendStr(buf, io->stdOut);

}

if (parserInfo.currType=='7' || parserInfo.currType=='8' || parserInfo.currType=='9') {

/* end of records */

break;

}

} while (1);

if (res==ERR_OK) {

CLS1_SendStr((unsigned char*)"\r\ndone!\r\n", io->stdOut);

} else {

while (AS1_GetCharsInRxBuf()>0) {/* clear buffer */

AS1_ClearRxBuf();

WAIT1_Waitms(100);

}

CLS1_SendStr((unsigned char*)"\r\nfailed!\r\n", io->stdOut);

/* erase flash again to be sure we do not have illegal application image */

if (BL_EraseAppFlash(io)!=ERR_OK) {

res = ERR_FAILED;

}

}

return res;

}

It first fills a callback structure of type S19_ParserStruct:

typedef struct S19_ParserStruct {

uint8_t (*GetCharIterator)(uint8_t*, void*); /* character stream iterator */

void *voidP; /* void pointer passed to iterator function */

uint8_t (*S19Flash)(struct S19_ParserStruct*); /* called for each S19 line to be flashed */

/* the following fields will be used by the iterator */

S19_FileStatus status; /* current status of the parser */

uint8_t currType; /* current S19 record, e.g. 1 for S1 */

uint32_t currAddress; /* current code address of S19 record */

uint16_t codeSize; /* size of code in bytes in code buffer */

uint8_t *codeBuf; /* code bufffer */

uint16_t codeBufSize; /* total size of code buffer, in bytes */

} S19_ParserStruct;

That structure contains a callbacks to read from the input stream:

static uint8_t GetChar(uint8_t *data, void *q) {

CLS1_ConstStdIOType *io;

io = (CLS1_ConstStdIOType*)q;

if (!io->keyPressed()) {

#if USE_XON_XOFF

SendXONOFF(io, XON);

#endif

while(!io->keyPressed()) {

/* wait until there is something in the input buffer */

}

#if USE_XON_XOFF

SendXONOFF(io, XOFF);

#endif

}

io->stdIn(data); /* read character */

if (*data=='\0') { /* end of input? */

return ERR_RXEMPTY;

}

return ERR_OK;

}

Parsing of the S19 file is done in S19_ParesLine() which is implemented in a Processor Expert component which I already used for another bootloader project:

This parser is calling my callback BL_onS19Flash() for every S19 line:

static uint8_t BL_onS19Flash(S19_ParserStruct *info) {

uint8_t res = ERR_OK;

switch (info->currType) {

case '1':

case '2':

case '3':

if (!BL_ValidAppAddress(info->currAddress)) {

info->status = S19_FILE_INVALID_ADDRESS;

res = ERR_FAILED;

} else {

/* Write buffered data to Flash */

if (BL_Flash_Prog(info->currAddress, info->codeBuf, info->codeSize) != ERR_OK) {

info->status = S19_FILE_FLASH_FAILED;

res = ERR_FAILED;

}

}

break;

case '7':

case '8':

case '9': /* S7, S8 or S9 mark the end of the block/s-record file */

break;

case '0':

case '4':

case '5':

case '6':

default:

break;

} /* switch */

return res;

}

Of interest are the S1, S2 and S3 records as they contain the code. With BL_ValidAppAddress() it checks if the address is within the application FLASH memory range:

/*!

* \brief Determines if the address is a valid address for the application (outside the bootloader)

* \param addr Address to check

* \return TRUE if an application memory address, FALSE otherwise

*/

static bool BL_ValidAppAddress(dword addr) {

return ((addr>=MIN_APP_FLASH_ADDRESS) && (addr<=MAX_APP_FLASH_ADDRESS)); /* must be in application space */

}

If things are ok, it flashes the memory block:

/*!

* \brief Performs flash programming

* \param flash_addr Destination address for programming.

* \param data_addr Pointer to data.

* \param nofDataBytes Number of data bytes.

* \return ERR_OK if everything was ok, ERR_FAILED otherwise.

*/

static byte BL_Flash_Prog(dword flash_addr, uint8_t *data_addr, uint16_t nofDataBytes) {

/* only flash into application space. Everything else will be ignored */

if(BL_ValidAppAddress(flash_addr)) {

if (IFsh1_SetBlockFlash((IFsh1_TDataAddress)data_addr, flash_addr, nofDataBytes) != ERR_OK) {

return ERR_FAILED; /* flash programming failed */

}

}

return ERR_OK;

}

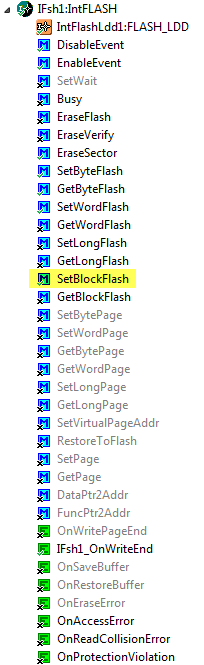

The Flash Programming itself is performed by the IntFLASH Processor Expert components:

This component is used for erasing too:

/*!

* \brief Erases all unprotected pages of flash

* \return ERR_OK if everything is ok; ERR_FAILED otherwise

*/

static byte BL_EraseApplicationFlash(void) {

dword addr;

/* erase application flash pages */

for(addr=MIN_APP_FLASH_ADDRESS;addr<=MAX_APP_FLASH_ADDRESS;addr+=FLASH_PAGE_SIZE) {

if(IFsh1_EraseSector(addr) != ERR_OK) { /* Error Erasing Flash */

return ERR_FAILED;

}

}

return ERR_OK;

}

Bootloader or Not, that’s the Question

One important piece is still missing: the bootloader needs to decide at startup if it shall run the Bootloader or the application. For this we need to have a decision criteria, which is typically a jumper or a push button to be pressed at power up to enter bootloader mode.

In this bootloader this is performed by BL_CheckForUserApp():

/*!

* \brief This method is called during startup! It decides if we enter bootloader mode or if we run the application.

*/

void BL_CheckForUserApp(void) {

uint32_t startup; /* assuming 32bit function pointers */

startup = ((uint32_t*)APP_FLASH_VECTOR_START)[1]; /* this is the reset vector (__startup function) */

if (startup!=-1 && !BL_CheckBootloaderMode()) { /* we do have a valid application vector? -1/0xfffffff would mean flash erased */

((void(*)(void))startup)(); /* Jump to application startup code */

}

}

The function checks if the ‘startup’ function in the vector table (index 1) is valid or not. If the application flash has been erased, it will read -1 (or 0xffffffff). So if we have an application present and the user does not want to run the bootloader, we jump to the application startup.

Below is the code to decide if the user is pressing the button to enter the startup code:

static bool BL_CheckBootloaderMode(void) {

/* let's check if the user presses the BTLD switch. Need to configure the pin first */

/* PTB8 as input */

/* clock all port pins */

SIM_SCGC5 |= SIM_SCGC5_PORTA_MASK |

SIM_SCGC5_PORTB_MASK |

SIM_SCGC5_PORTC_MASK |

SIM_SCGC5_PORTD_MASK |

SIM_SCGC5_PORTE_MASK;

/* Configure pin as input */

(void)BitIoLdd3_Init(NULL); /* initialize the port pin */

if (!BL_SW_GetVal()) { /* button pressed (has pull-up!) */

WAIT1_Waitms(50); /* wait to debounce */

if (!BL_SW_GetVal()) { /* still pressed */

return TRUE; /* go into bootloader mode */

}

}

/* BTLD switch not pressed, and we have a valid user application vector */

return FALSE; /* do not enter bootloader mode */

}

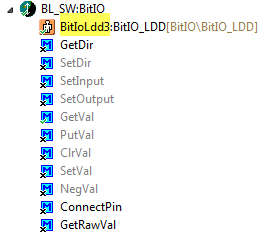

I’m using BitIOLdd3_Init() to initialize my port pin, which is part of the BitIO component for the push button:

💡 When creating a BitIO component for Kinetis, Processor Expert automatically creates a BitIO_LDD component for it. As I do not have control over the name of that BitIO_LDD, I need to use in my bootloader whatever Processor Expert has assigned as name.

I’m using PTB8 of the Freedom board, and have it connected to a break-out board (pull-up to 3.3V if button is not pressed, GND if button is pressed):

You might wonder why I have to initialize it, as this is usually done automatically by PE_low_level_init() in main()? The reasons is: I need to do this *before* main() gets called, very early in the startup() code. And that’s the reason as well why I need to set the SIM_SCGC5 register on Kinetis to clock the peripheral.

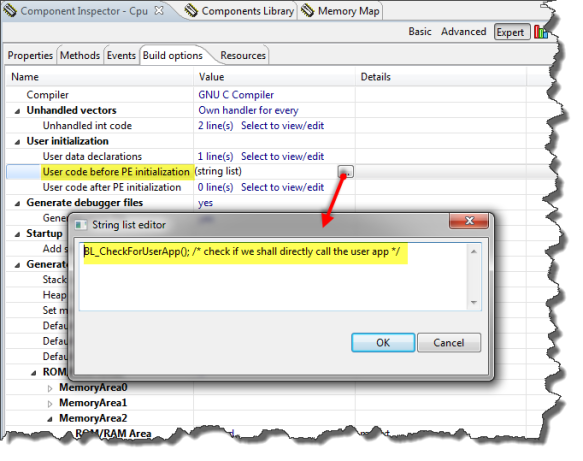

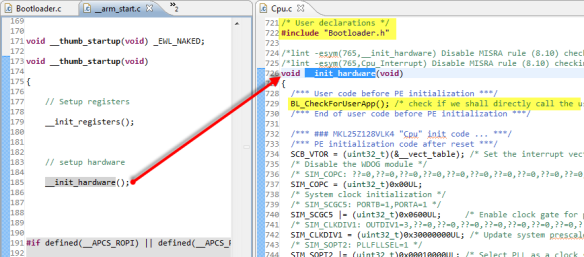

Inside the CPU component properties, there is a Build option setting where I can add my own code to be inserted as part of the system startup:

To make sure it has the proper declaration, I add the header file too:

These code snippets get added to the __init_hardware() function which is called from the bootloader startup code:

This completes the Bootloader itself. Next topic: what to do in the application to be loaded…

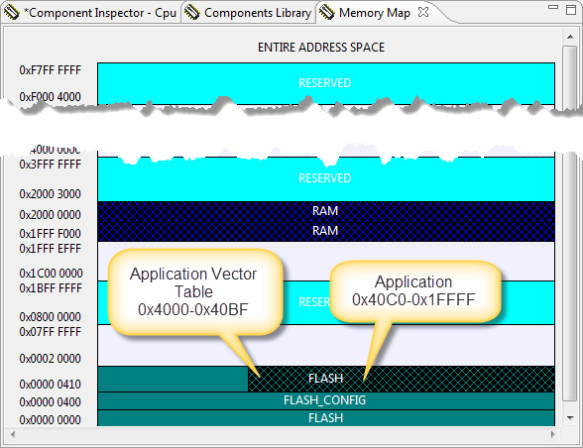

Application Memory Map

As shown above: the bootloader is sitting in a part of the memory which is not available by the application. So I need to make sure that application does not overlap with the FLASH area of the bootloader. My bootloader starts at address 0x0000 and ends at 0x3FFF:

While the application can be above 0x4000. These numbers are used in Bootloader.c:

/* application flash area */ #define MIN_APP_FLASH_ADDRESS 0x4000 /* start of application flash area */ #define MAX_APP_FLASH_ADDRESS 0x1FFFF /* end of application flash */ #define APP_FLASH_VECTOR_START 0x4000 /* application vector table in flash */ #define APP_FLASH_VECTOR_SIZE 0xc0 /* size of vector table */

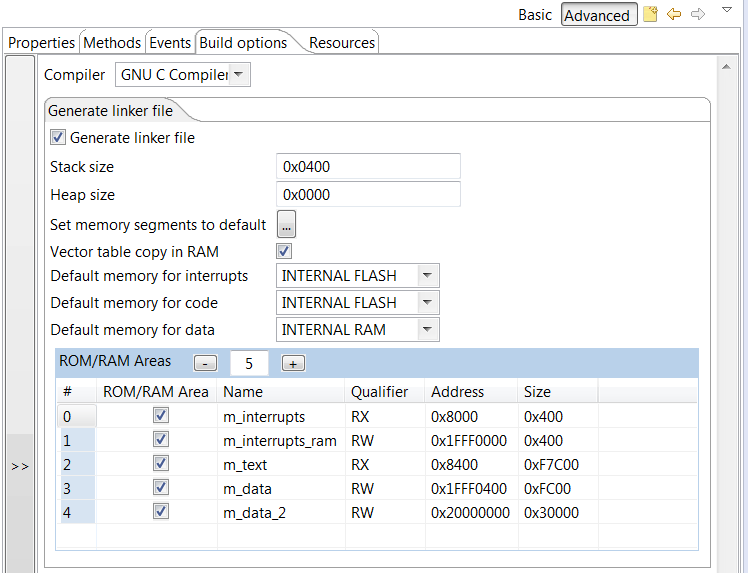

The application just needs to stay outside the FLASH used by the bootloader:

To make this happen, I need to change the addresses for m_interrupts and m_text in the CPU build options:

That’s it 🙂

💡 As for the ARM Cortex-M4/0+ do not need to copy the vector table in the bootloader to a different location, I can debug the application easily without the bootloader.

S-Record (S19) Application File Generation

The bootloader loads S19 or S-Records. This post explains how to create S19 files for Kinetis and GNU gcc.

Code Size

The bootloader is compiled with gcc for the FRDM-KL25Z board. Without optimization (-O0), it needs 13 KByte of FLASH. But optimized for size, it needs only 8 KByte 🙂 :

text data bss dec hex filename 8024 24 2396 10444 28cc FRDM_Bootloader.elf

Summary

With this, I have a simple serial bootloader for only 8 KByte of code. The bootloader project and sources are are available on GitHub here.

And I have several ideas for extensions:

- Using a memory stick to load the appliation file (USB MSD Host).

- Using a SD-Card interface with FatFS.

- Using a USB MSD device to load the file.

- Performing vector auto-relocation: the bootloader should detect the vector table at address 0x00 of the application file and automatically relocate it to another location in FLASH. That way I can debug the Application without change of the vector table.

- Making sure it runs on other boards and microcontroller families.

- Creating a special component for the bootloader.

While the bootloader only needs 8 KByte for now, I keep the reserved range at 16 KByte, just to have room for future extensions.

Happy Bootloading 🙂

Thank you for sharing this, Erich. I will almost certainly be adapting this for use in an SD card-based and eventually an over-the-air (WiFi) bootloader. Hopefully, I can contribute something back to your examples section on Github if I am successful.

Your blog has been my textbook for the past few weeks and will probably continue to be that in the near future.

LikeLike

Why can’t I find S19 in my processor expert components? (Also, Shell, Utility…)

LikeLike

Hi Liz,

you need to load the additional Processor Expert components first. See https://mcuoneclipse.com/2013/05/09/processor-expert-component-peupd-files-on-github/

LikeLike

Thank you!

LikeLike

I must update… okay I see. Sorry!! 🙂

LikeLike

Hey Erich,

I don’t have a switch board available, do you have any ideas how to avoid using one? Is using the TSI component of KL25z practical?

Thanks, Liz

LikeLike

Hi Liz,

you could consider to use the reset button:

LikeLike

Thank you! I have the bootloader somewhat working but I think I’m having trouble with the application part. I basically just made a copy of the FRDM_Bootloader project you provided and changed the Memory Areas like you showed in your tutorial above (for applications). I have the .s19 file being created but when I send it to the FRDM_Bootloader project through serial, I keep getting errors saying “Failed or unknown command” as it goes through the whole .s19 file.

Is there something I’m missing? Is the application code not supposed to have bootloader files on it?

Thank you,

Liz

LikeLike

Hi Liz,

are you using “BL load s19” as command?

LikeLike

Yes I am. I used “BL load s19” it erases and waits for the s19… then I send the s19 file.

LikeLike

I know that sending the S19 file is the most critical part. Are you sure you use an S19 file? Which program do you use to send the file? Can you post what you get after ‘waiting for the S19 file…’?

LikeLike

This is what I see while sending the s19 file…

Erasing application flash blocks…done!

Waiting for the S19 file…

S0 address 0x00000000ERROR!

Failed at address 0x00000400

failed!

Erasing application flash blocks…done!

*** Failed or unknown command: BL load s19

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: S11340000030002035650000B151000

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: 0BD510000B2

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: S1134010BD510000BD510000BD51000

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: 0BD51000064

… and it goes on and on with the failed or unknown commands, I’m guessing it goes through the whole s19 file.

I used https://mcuoneclipse.com/2012/09/13/s-record-generation-with-gcc-for-armkinetis/ to make my project generate a s19 file, I was originally getting hex files but then I read in the comments to that tutorial that you can change the suffix.

I use the terminal you recommended here to send the s19 file.

Thanks,

Liz

LikeLike

Can you try to increase the delay (the dialog next to ‘send file’)?

LikeLike

No success increasing the delay… is there an project of an application I can try using instead of using my own? Thank you.

LikeLike

I have sent you an S19 file I used by email.

LikeLike

Hi Erich,

I also meet the same issue. S19 file can not load correctly.

Can you send me you S19 file?

LikeLike

https://github.com/ErichStyger/mcuoneclipse

It’s in the BL_Blink project.

LikeLike

Thanks Erich, it worked

LikeLike

Hi Erich,

I’m having exactly the same problem as Liz below. I’ve tracked the parse error down to the second line in my S19 file, which uses the address 0x0400:

1: S01100004D4B32305F426C696E6B2E7331399A

2: S1130400FFFFFFFFFFFFFFFFFFFFFFFF7EFFFFFF79

3: S113400000000020CD480000694400008544000001

4: S11340108544000085440000854400008544000078

…

It looks like that line is related to the Flash memory configuration which resides at 0x0400, and I don’t quite know what to do about it or how you worked around that. Here is the corresponding section in my linker script:

MEMORY {

m_interrupts (RX) : ORIGIN = 0x00004000, LENGTH = 0x000001C0

m_text (RX) : ORIGIN = 0x000041C0, LENGTH = 0x0001BE40

m_data (RW) : ORIGIN = 0x1FFFE000, LENGTH = 0x00002000

m_data_20000000 (RW) : ORIGIN = 0x20000000, LENGTH = 0x00002000

m_cfmprotrom (RX) : ORIGIN = 0x00000400, LENGTH = 0x00000010

}

I’m going to try removing that line and sending the S19 file again, but please let me know if you have any better ideas.

Thanks!

Vishal

LikeLike

Hi Vishal,

I have committed my example project on GitHub. The important thing is that hte memory map is correct. See as well how the burner.bbl file is used in that project:

https://github.com/ErichStyger/mcuoneclipse/tree/master/Examples

LikeLike

Thanks, Erich! That was very helpful. Turns out, I had the Flash configuration field enabled in the CPU component, which was generating that S19 record.

LikeLike

I am working my way up to a Wifi-based firmware update procedure, as I mentioned in an earlier comment. The bootloader is basically working at this point, but I am having an issue with the button debouncing wait inside of BL_CheckBootloaderMode:

WAIT1_Waitms(50); /* wait to debounce */

After entering this code, the program seems to run some of the wait_cycles code a few times before resetting. I’m not sure why this happens, but I am using the FRDM K2050M, and I’ve made this project from scratch so there could be some tiny difference between my PE component setup and your FRDM KL25Z project that is messing with the flow. I can’t imagine what, since the WAIT component doesn’t require any initialization, and all the functions do is wait. Perhaps there is some incompatible assembly code in the lowese-level wait-cycle routines?

LikeLike

The Waitms(50) is simply to wait for some time in order to debounce the push button. As bouncing depends on the button, 50 ms might not be enough (I have seen buttons bouncing for as much as 200 ms). The other thing is that in earlier versions of the Wait component, the timing was not always correct. The new component on the GitHub has the fix (I’m using “Version : Component 01.059”, you can get that information from the WAIT1.c file. In any case, if this should be the problem, simply increase the waiting time to say 500 ms and let me know if this helps.

LikeLike

Sorry to keep bugging about this bootloader… I’ve been having a problem where the application will not run after successfully loading the s19 file and then restarting or running the program again without pressing down the button that loads the bootloader.

For example:

1. Press button and run project. “BL load s19” and send the s19 file.

2. Stop the debugging process.

3. Debug program again without pressing down button that loads bootloader.

4. EITHER a. Bootloader will run again (red light blinking). OR b. I get this error: No source available for “0xFFFFFFFE (0xFFFFFFFE)() ”

As I stepped through, the condition that doesn’t allow the application to run is when the BL_CheckBootloaderMode() returns FALSE to the if statement in CheckForUserApp(), the FALSE ends up being a “ÿ” which won’t allow the if statement to be completely true. I hope that’s clear.

I tried also using the reset button as well as soldering wires and using test leads as a “button press” similar to this tutorial but I keep getting this error. I haven’t changed anything from the projects you posted on GitHub, either.

LikeLike

Hi Liz,

>>3. Debug program again without pressing down button that loads bootloader.

Keep in mind that depending on how you debug, this will erase the whole flash, so only the bootloader will present on the target.

If that ‘No source available’ shows up, then this means that the debugger initial PC is set at this address where is no code, or that the ‘application code detection’ somehow failed to properly detect the application mode.

That “ÿ” is probably a debugger display problem, as it tries to show the value as character. Could you check the value in hex mode?

And: are you modified my unchanged example code, or your own one?

LikeLike

I did not modify your example code.

I made a bool variable, checkMode, to see what BL_CheckBootloaderMode() returns, it shows “checkMode = ÿ”, when I hover over the variable in the code. But, when I go into the “Variables” tab I see just a space like so, ‘ ‘ , with the single apostrophes. I made a uint32_t variable and set checkMode to it and in the “Variables” tab, the uint32_t variable reads 0. Stepping through, BL_CheckBootloaderMode() is for sure returning FALSE.

The “Variables” tab is where to see the hex value, correct?

LikeLike

Yes, you can use the variables view for this. To change the variable format right click on it and select Format > Hexadecimal.

See as well https://mcuoneclipse.com/2012/10/01/debugging-variables-in-hexadecimal-with-eclipse/

LikeLike

It shows that checkMode in hex is 0x00, and startup is not equal to -1, so I have no clue why the if statement isn’t allowing me in.

LikeLike

Hi Liz,

The code in BL_CheckBootloaderMode() is the following:

if (!BL_SW_GetVal()) { /* button pressed (has pull-up!) */

WAIT1_Waitms(50); /* wait to debounce */

if (!BL_SW_GetVal()) { /* still pressed */

return TRUE; /* go into bootloader mode */

}

}

/* BTLD switch not pressed, and we have a valid user application vector */

return FALSE; /* do not enter bootloader mode */

The logic is the following: if the button is pressend, then the pin returns 0 (FALSE). So pushing the button means that it gets a low voltage. If the button is not pressed, it shall be HIGH (logic high level). Typically this means that a normal button needs to have a pull-up resistor (either internally or externally). Do you have this? The button (BL_SW) shall not be floating. It needs to be either LOW if pressed, and high if not pressed.

LikeLike

Erich,

I have GND and PTB8 connected and working as a button press and P3V3 with a resistor and PTB8 connected when I want no button pressed (not working).

I feel like I want to give you more information… but I’m not sure what else to give.

Thanks,

Liz

LikeLike

Hi Liz, how much is your resistor? It should not matter, but if using the pin as input and 3.3V, you do not need a resistor.

LikeLike

3 Kohms. Remember I mentioned using the restart button and it showed “no source available” and such? When I Run instead of Debug, without triggering the button, the chip goes into bootloader mode then if I Ran it again it the RGB LED does not flash. So maybe the application code isn’t found…

I just noticed… do you think my MCU Wizard and Tools Plugin being expired has something to do with this?

LikeLike

No, the wizard or tool plugins do not expire. Only if your evaluation license expires, your code size is limited for debug to 32 Kbyte. I don’t think you have more than that.

Try it withoug the 3 KOhms resisotr. And use ‘Reset’, not ‘Restart’: restart performs a new download which is not what you want.

LikeLike

I’m sorry, I did use the reset, I accidentally called it restart. I put the resistor on after you mentioned it for the pull up so I have tried it without the resistor. It’s just not entering application mode. When I run it and the bootloader doesn’t come on, there is no action in the RGB LED, even after I sent the BL_Blink s19 file to make it blink blue. Maybe I should download CW again, maybe that will miraculously solve my issue.

LikeLike

Hi Liz,

I don’t belive that a new CodeWarrior installation will solve your problem. It must be something different. I have not had the time to try with the hardware my project again, but maybe I should now.

LikeLike

Okay. I am wondering, when I initially set up OpenSDA and put files in that bootloader, I had some troubles. Do you think those troubles could affect what is going on now? Should I look into getting a new board to try?

LikeLike

Hi Erich,

Your Post for Serial Boot-loader is a great help for understating the basics of how it worked. Thanks for posting it.

Do you have any serial bootloader post for MC9S08SH8 like KL25Z….

i was using the AN2295SW bootloader but couldn’t find any for MC9S08SH8 and its bit difficult to understand…. Please help me to figure this out….

Thanks in advance…

Regards,

Swapnil

LikeLike

Hi Swapnil. No, I do not have a post on SH8, and I do not have that hardware neither. But my KL25Z project is with Processor Expert, and with this it is applicable and should work with the S08 too (or with any device supported by Processor Expert). The principles are the same.

I hope this helps.

LikeLike

Thanks erich, i am working with your component….will let you know if it is successful…

LikeLike

How to generate .s19 file and .bll file????

LikeLike

See

and

LikeLike

Hi Erich,

before all thanks alot for your work and this site. I was losing every hope on using the freedom board for my purposes before to discover your site.

Now i need a little help to finish the mixing of your serial bootloader with the CDC virtual COM firmware. I’ve a strange behavior with my freedom board (KL25Z).

If I try to load and start the bootloader’s firmware with the openSDA cable plugged in and the debugger running all goes fine. I can enter in bootloader mode or in application mode without any problem.

But if I disconnect the openSDA cable or I turn off the debugger, after the device’s reset, the bootloader mode doesn’t start anymore. The application mode starts correctly but, the bootloader mode causes the reset of the KL25 mcu when the BL_CheckBootloaderMode reach this point of the code.

if (!BL_SW_GetVal()) { /* button pressed (has pull-up!) */

WAIT1_Waitms(50); /* wait to debounce */

if (!BL_SW_GetVal()) { /* still pressed */

return TRUE; /* go into bootloader mode */

}

}

I’ve tryed also to maintain only the return TRUE condition without the other part of the code but the board doesn’t start in bootloader mode without the openSDA connected and the debugger running.

Thank in advice for your help,

Walter

LikeLike

What are you using as the bootloader switch? The board reset button or your own button? I would need to try it out myself first, but maybe there is a delay or something which makes the boot process of the microcontroller different?

LikeLike

Hi,

for the bootloader switch I use the pin PTB9 with an external pull-up of 3kohm.

Currently I was able to solve the problem adopting a led, used to understand where the execution of the firmware crash. So I’ve discovered that the execution of the “__arm_start.c” file never reach the instruction “exit(main(0, argv));” without the debugger of the codewarrior.

This seems to happen because of some #ifdef instruction before the exit directive. Following what is written in your article that talk about the optimization of the start up procedure (https://mcuoneclipse.com/2012/11/11/optimizing-the-kinetis-gcc-startup/) I’ve removed this ifdef and now the device works fine also without the debugger.

The removed code is:

#if defined(__SEMIHOSTING)

// semihost initializations

__init_semihost();

#endif

// call main(argc, &argv)

#if SUPPORT_SEMIHOST_ARGC_ARGV

exit(main(__argc_argv(__MAX_CMDLINE_ARGS, argv), argv));

#else

I don’t understand why, without the debugger this part of code inhibits the execution of the exit(main()) instruction but now the code works.

if I can explain why I would be very happy…

Hi and good work,

Walter

LikeLike

Hi Walter,

interesting, interesting.

So this means that ‘semihosting’ was enabled in your project? Can you check your compiler/build tool settings if you have semihosting enabled (I never use it because of these kind of problems).

What Semihosting does is: it allows the application to do printf(), and it will be catched by the debugger and sent to the debugger console in the debuggger. Great for demo purposes, but typically this does not work or block the target without debugger attached 😦 I think this is what you are seeing?

LikeLike

digging more into semihosting: this is enabled if you select ‘Debugger Console’ under ‘I/O Support’ during project creation (Language and Build Tools Options step).

Text shown in this dialog:

‘Debugger Console’ support will be included in the project.

* This setting configures how the GCC-ARM library deals with the console (e.g. printf() or puts()). With ‘Debugger Console’ the library uses a virtual connection with the debugger (also known as ‘semi hosting’).

What it does: it sets up the library (Librarian in build settings) to ‘ewl_hosted’: change it to ewl_noio.

I think this would have fixed it for your project too.

LikeLike

Hi Erich,

thank you very much for your explanation. I can confirm that “semihosting” was active.

How can I turn it off without creating a new project?

Thanks again,

Walter

LikeLike

Go to the project settings, then C/C++ Build > Settings > Librarian and then select the ewl_noio library model.

That should do it. I hope this helps.

LikeLike

Dear sir,

Do you know to speed up to write s19 to flash? Because delay 1ms is too slow. But use 0ms, it will crash.

Thanks.

BR,

Sean

LikeLike

Hi Sean,

I have not measured it. But that 1ms is not the flash programming speed, it is about the communication with the host. If not using handshaking, you easily run into a RX buffer overflow. I have not completely solved this on my end, but I think some advanced buffering would be needed?

LikeLike

Hi Erich,

Thanks for your reply.

LikeLike

Hi Erich

I can not see “Internal Peripheral” in my “MCU Component Inspector”:

Just “Clock setting” “CPU interrupt” and “Clock configuration”

LikeLike

Hello,

Looks like you have not enabled ‘Expert’ mode in the inspector. See https://mcuoneclipse.com/2013/01/27/enabling-the-expert-level-in-processor-expert/

LikeLike

Hi Erich,

S19 file is “hex” file in FLASH folder, correct?

LikeLike

Yes. Unfortunately that gcc build integration plugin in Eclipse uses a hardcoded .hex extension for all files, even if it is an S19 file. You can verify this if you open the file with a text editor. More details about this in https://mcuoneclipse.com/2012/09/13/s-record-generation-with-gcc-for-armkinetis/

LikeLike

Hi Erich.

Do you have plan to create a USB CDC bootloader for KL25Z?

I’m intending to do it but I’m not sure it’s impossible or not, because USB CDC driver is quite big.

LikeLike

Yes, such a USB CDC bootloader is on my wish list for a very long time. But as you say: a USB stack is much more complicated and bigger than an serial driver. So no surprise that if this is double more of the size of a serial bootloader. Simply because a USB driver and stack is a very big thing.

LikeLike

Hi Erich.

I completely download your Boot Loader source to KL25Z FRDM. When debugging, I receive following log file in Terminal screen:

It didn’t stop

————————————————————–

FRDM Shell Bootloader

————————————————————–

CLS1 ; Group of CLS1 commands

help|status ; Print help or status information

BL ; Group of Bootloader commands

help|status ; Print help or status information

erase ; Erase application flash blocks

restart ; Restart application with jump to reset vector

load s19 ; Load S19 file

CMD> *** Failed or unknown command: ——————————-

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: ——————————-

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: FRDM Shell Bootloader

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: ——————————-

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: ——————————-

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: CLS1 ; Gro

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: up of CLS1 commands

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: help|status ; Pri

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: nt help or status information

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: BL ; Gro

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: up of Bootloader commands

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: help|status ; Pri

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: nt help or status information

*** Type help to get a list of available commands

CMD> *** Failed or unknown command: erase ; Era

*** Type help to get a list of available commands

LikeLike

It looks to me like your terminal program is echoing all incoming characters back? Have you configured it in a loop-back mode?

LikeLike

it’s my stupid bug, mistake from uart cable, It’s leaked. (I’m using USB UART converted IC).

It worked very well now.

LikeLike

Hello Erich,

This is a very informative tutorial thanks for this,i would like to implement this boot loader code into my k60 core(MK60FN1MOVLQ12),i am using the TWR-K60F120M board , but the processor expert settings are a bit different ,for instance, there is no specific memory protection area where i enter the addresses to protect.

Could you please instruct me on the processor expert settings for k60 core cpu. I use code warrior 10.3 and have already installed all your latest PE packages.

LikeLike

I have not checked the details, but I would be surprised if the K60 does not have this protection mechanism.

In any case: try to get it working without the protection (as a proof of concept): the protection is only needed for ‘production’ where you want to avoid that the bootloader gets overwritten.

And CodeWarrior 10.3 is pretty old: Why are you not using 10.5 (latest current version)?

LikeLike

There is a protection detail present but,i am not able to enter the address to protect, i will try to get it working without the protection.

I am using cw 10.3 because there seems to be some problems programming in cw10.5 via PE multilink programmer.

LikeLike

What kind of problems? I’m using the PE multilinks with 10.5 without problems.

LikeLike

It sometimes does not program the controller and gives a flash error,and frequently it disconnects when in middle of a debug session.I noticed these errors come once i generate(in 10.5) the code from Processor expert.If i just copy a project previously created in cw 10.3 and run it using 10.5 it programs correctly.

LikeLike

That sounds really strange. Maybe you should submit this to P&E and or the Freescale forum?

LikeLike

sorry for the late reply,was out of town for a few days 🙂

Yep i will.

comming back to my bootloader,i keep getting a HARD FAULT status(ISR) when ever i add the serial_ldd module in my BL_CheckForUserApp() function.

Any idea why that is happening?

Here is my full function:

#include “bootloader.h”

void bootloader_usercode()

{

boot_serial_ptr = AS1_Init(NULL); //if removed the function it works correctly.

char str[20] = “BOOTLOADER ENTERED.”;

//clock all the port pins.

SIM_SCGC5 |= SIM_SCGC5_PORTA_MASK |

SIM_SCGC5_PORTB_MASK |

SIM_SCGC5_PORTC_MASK |

SIM_SCGC5_PORTD_MASK |

SIM_SCGC5_PORTE_MASK;

BitIoLdd1_Init(NULL);

if(Bit1_GetVal())

{

boot_flag = FALSE;

AS1_SendBlock(boot_serial_ptr,str,sizeof(str));

//enter bootloader sequence.

}

else

{

boot_flag = TRUE;

//proceed to user code operation.

}

}

LikeLike

That init of AS1_Init() looks not good, and too early. Try to move it later in the sequence, as clocks/etc need to be set up.

And use my component (https://mcuoneclipse.com/2012/12/28/a-processor-expert-component-to-help-with-hard-faults/) to locate where it is crashing.

I hope this helps.

LikeLike

Hi Eric

I am working with K64, using Code Warrior 10.6,the boot loader loads the app and work fine with simple project led_blink. but when try to load my application project srec file which is pretty big, I am getting Hard fault interrupt after some half the file is loaded.after debugging using Hardfault processor component, I see it is Fault address error “Precise data bus error” bit set on

SCB->CFSR register. I do see fault address loaded in the register SCB->BFAR.

do you know what could be causing this.

LikeLike

I have not seen something like this. Are you crossing some memory boundaries? Is it always at the same place?

LikeLike

I see some strange address which is out of range in the SCB->MMFAR and SCB->BFAR Register, I dont know how I am getting that. its always at the same place.

LikeLike

I would try to load a program to that same place to see if the problem is related to the place where you load it, or if it is related to the size of the binary.

LikeLike

‘314D0″this was the last address I saw on terminal. I have copied a part of srec file icluding that address.

S214031450ACF1040C2CE9FF00F0BC8CF3088862B6F0

S214031460704700BF70474FF08002D0E84F1F002937

S2140314700CBFC0E8432F00F003B8002B7FF4F5AF92

S21403148008467047EFF309807047EFF3088070470C

S21403149080F308887047EFF30380704762B670479F

S2140314A072B670477046704778467047EFF31480FD

S2140314B0704700BF2400002000ED00E0000000108D

S2140314C020ED00E0FF000000000000080000000020

S2080314D0F613030004

S2140314D4EC1000206C0E0020F8270020782500204E

S2140314E4F8220020782000206C130020981C00208B

S2140314F400000000FFFFFFFFE9FA00000000000001

S21403150400000000000000000000000000000000CF

S2140315148192020041940200A19502000196020002

S2140315242D960200C996020000000000E996020008

S21403153459970200B978010000000000000000007B

LikeLike

Hi Eric,

the issue looks to be with Srec file generation

the address it fails is at “314D4” which is intermediate address where processor fails to flash.

do you have any option to changes the srec file generation

LikeLike

Please help me with that: what is wrong with that address 0x314D4?

What would you like to change?

And in case this helps: this is a powerful tool for S-Record manipulation: https://mcuoneclipse.com/2015/04/26/crc-checksum-generation-with-srecord-tools-for-gnu-and-eclipse/

LikeLike

if you see my srec file below all the address are in boundary range

S2 31450

S2 31460

S2 31470

……

…..

but at the point where it starts failing, srec has Boundary range has

S2 314D4

S2 314E4

here flash block address has changed and I get that Hard fault interrupt.

LikeLike

how could I set up srec generation in code warrior setting

so that block address remains multiple of 16

LikeLike

CodeWarrior cannot do this, you need to use srec_cat (http://srecord.sourceforge.net/man/man1/srec_cat.html). Try option −Output_Block_Alignment

LikeLike

Hi Eric

how do I use the srec_cat in codewarrior

do you have syntax or example of srec_cat used in code warrior for −Output_Block_Alignment

LikeLike

You can use it in CodeWarrior the same way as described in https://mcuoneclipse.com/2015/04/26/crc-checksum-generation-with-srecord-tools-for-gnu-and-eclipse/. You can use a post build or multiple postbuild steps (see https://mcuoneclipse.com/2014/09/23/executing-multiple-commands-as-post-build-steps-in-eclipse/). This post shows how to use post build steps in CodeWarrior: https://mcuoneclipse.com/2013/10/29/s-record-manipulation-with-gnu-objcopy-and-burner-utility/

I do not have an example ready for you, have a look at the srecord excellent manual and help pages (http://srecord.sourceforge.net/man/man1/srec_examples.html).

I hope this helps.

LikeLike

hi Eric,

I was able to use srec cat for block alignment and that fixed download issue

but now I have other issues, i am getting interrupt at Unhandled_ivINT_Reserved7.

I tried downloading and running application from debugger and it does the same. application halts at interrupt “Unhandled_ivINT_Reserved7”

if I change the Interrupt memory address and Memory address to default at processor expert->cpu->build options

and download with debugger it works fines.

I have below setting memory address for which i am seeing a problem

memory area 0 – interrupt

address -> 0x7410

size -> 198

memory area 1 – m_text_0000198

address -> 0x75a8

size -> 268

memory area 2 – m_text

address -> 0x8000

size -> F8000

LikeLike

Hi Niranjan,

hard to tell me what is going wrong 😦

Is this Unhandled_ivINT_Reserved7 present in your vector table (which vector number?).

I think somehow your vector table might not be properly setup.

And you need to find out what is causing this interrupt in your application. I would step through it with the debugger to see what is causing it.

LikeLike

Hi Eric,

I see that is vector 7, this interrupt occurs when scheduler started by calling this function “_sched_start_internal” this is called _mqxlite().

i did checked the map file and linker file interrupt vector set right to address where it is configured (0x7410)

LikeLike

As I’m not using MQX, I’m affraid that I cannot really help you here 😦

LikeLike

Hi Eric,

finally issue got solved, i changed the application start address from 0x7410 to 0x7400.

it started working with no interrupt.

I might MQX has boundary issues.

thank you very much 🙂 .

LikeLike

GREAT 🙂

LikeLike

yes i got it now.should add it much later.

The code seems to be working(i can see the serial data showing on my console)

But now i am getting a few another strange problems:

Firstly,

When i debug the code is functions correctly

But when i program,and try again it doesn’t seem to work.

Secondly,

(When debugging )I keep getting stuck in hard fault ISR whenever i enter “BL erase”.

Thirdly,

I am a little confused as to why the MIN_APP_FLASH_ADDRESS and APP_FLASH_VECTOR_START in bootloader.c have got the same value?

LikeLike

Update:

I figured out the HARD FAULT error

Had given the wrong flash start adress

But now while programming the application gives me an error

CLS1 ; Group of CLS1 commands

help|status ; Print help or status information

BL ; Group of Bootloader commands

help|status ; Print help or status information

erase ; Erase application flash blocks

restart ; Restart application with jump to reset vector

load s19 ; Load S19 file

Erasing application flash blocks…done!

S11300204D1200004D1200004D1200004D120000503322E68657804

10 address 0x00000S000ERROR!

0Failed at1 address 03×00000000

S9030C21CF000000FE0000000000000000000000E2

failed!

Erasing application flash blocks…done!

*** Failed or unknown command: BL load s19

*** Type help to get a list of available commands

CMD>

Cannot make sense as to where it is giving error ??

LikeLike

Maybe there is something wrong with your application S19 file? Can you try the one from my example project in

https://github.com/ErichStyger/mcuoneclipse/tree/master/Examples

?

LikeLike

Would vector redirection be needed if there was no need for interrupts in bootloader routines?

LikeLike

Yes, if you are not going to use any interrupts in the bootloader (well, except reset of course), then you do not need to remap vectors.

LikeLike

Hi Erich,

Thanks for the bootloader tutorial!

I have converted the bootloader to a KL46Z project using the USB CDC component instead of the Asynchronous Serial component. The bootloader firmware runs and its possible to send S19 files to it. However, the S19 file parsing always fails within the first couple of lines. I saw a comment above that discussed disabling the “Flash configuration field” in the CPU component to make the bootloader work. I’m not sure if this had to be done on the bootloader firmware or the test app (a blink app) or both. In any case, what effect has this on the bootloader? I tried disabling this option for the blink app and this caused the bootloader to continue to parse more lines past the original parsing error I saw (0x400). Howevever, the bootloader still shows parsing errors in the lines that follow. We’re running the application at 0xA000 and the first line loaded (0xA000) causes a “Fail at address…” error which doesn’t make sense to us at the moment.

Thanks in advance Erich. Any insight would be appreciated!

LikeLike

Hi Carlos,

first, make sure your S19 file is correct. I realized that something was wrong with the Blink_LED project I had published on GitHub. it was using the Burner.exe to generate the S19 file, and that S19 file was incorrect (S19 lines at the end were missing). I fixed that in the Blink_LED project (not using the burner for the S19 file, but using instead the GNU objcopy instead). You might check this out.

The other thing is: you need to be careful not to send the data too fast to the bootloader (there is no flow control). I know this is not ideal, but I had these parsing errors with the serial bootloader too if sending the file too fast. That’s why I was using that Terminal program shown in the post with a delay for each character sent. So what I suggest is that you slow down as well the speed of sending/receiving the data just to see if this helps?

LikeLike

Hello again,

I just wanted to mention that we have already tried checking that we typed in the correct addresses for the global variables in Bootloader.c.

We’ve closely followed with all the steps in your tutorial with the exception of using the USB CDC component and with starting our application’s address at 0xA000 instead of 0x4000. Other than that the bootloader seems to work. For example the erase instruction works fine.

Thanks again!

LikeLike

Hi Carlos,

see my other comment: I believe it has something to do with the speed the data arrives at the bootloader. The erase is probably not a problem because it does not need data for it. But if you send data too fast while it is programming, then because of no flow control data gets received in a corrupted way (bytes in the S19 missing).

LikeLike

Hi Erich,

Thanks for the comment about the delay! We can now run the bootloader on the FRDM-KL46Z with USB CDC instead of UART.

Now we’re trying to step into the Bootloader without using a button. The code is essentially the same as yours except we have a timeout loop that determines whether the processor will stay in bootloader mode or if it will run the application. The loop runs for ten seconds upon power up. If any character is received via USB then the processor remains in bootloader mode. Otherwise the application code is supposed to run. The reason is that we’re developing a custom board without buttons.

However, we have two issues we’re trying to solve:

1) The bootloader sometimes erases the application code upon reset (either by pushing the FRDM-KL46Z’s reset button or by issuing “BL restart”). We have commented out the two calls for the flash erasing procedures during the S19 load feature. But we still see that this happens sometimes.

2) At other times the application seems to be downloaded (we check this by running “BL status”) but resetting the board will not run it. Rather it repeatedly seems to reset at the ten second intervals. Sometimes it seems like the application code has been partially erased.

Other concerns:

a) We’re concerned that the reason why our blink app works with the button-capable bootloader is that we’re not implementing interrupts and/or because we aren’t relocating the application’s interrupt vector table through using the VTOR register. Our end application needs interrupts so we think that we need to relocate the interrupt vector table to 0xA000. What’s your opinion on this matter?

b) Since the bootloader has used the stack before we jump into the application, don’t we need to re-initiallize the stack before we jump into the application

c) What’s the reason for displaying the first and fourth words when asking for the status (BL status)? Wouldn’t we want to know only the first two words: the stack pointer and the reset vector?

Here’s a link to our code. Perhaps it would be easier to diagnose the issues by looking at it. The only code differences are a couple of lines at the beginning of BL_Run() and the fact that we commented out the flash erasing calls within the load S19 function and the BL_CheckForUserApp().

https://www.dropbox.com/s/d6mi5uonemovnvn/IMA_BOOT.zip

Thanks again!

LikeLike

Hi Carlos,

wow, a lot of questions! Unfortunately it will be hard for me even check your source code, simply not having time for everything. But maybe someone else who reads this can comment.

Here are my thoughts:

1) if the bootloader erases the application code, check the conditions who is causing this. Maybe you have glitch somewhere?

2) yes, my simple implementation does not check for a ‘finished’ status. There should be a verify and CRC added for additional checks.

a) Yes, if your application is using interrupts/different interrupt vectors, you need to relocate the vector table.

b) Up to you, resetting the stack pointer should be enough (you do not need to initialize the stack memory, but you can).

c) I simply show the first two 32bit words of the application space so I can see if they are erased or not. Of course you could change that to show anything else, including SP and PC.

I hope this helps,

Erich

LikeLike

Hi Eric

Im working with Carlos on the bootloader project. We can now download and run the simple blink program via the bootloader(not using any interrupts). Our real application uses interrupts and it freeses. I have downloaded via PE programmer and run the real application from address 0xA000 and it works well(vectors a A000 too). When I burn the bootloader and download the real appication via it (and redirect the vectos to the start of the application in Flash: SCB_VTOR= (uint32_t)APP_FLASH_VECTOR_START;), the program freeses (seems to be a hard fault), so I suspect problems with interrupts.

I have seen in several app notes that when redirecting the vector table, it is put in RAM. I have not foud the argument for that, do you know why?

Best regards

Baldur

LikeLike

Hi Baldur,

for which architectures are the application notes? Many architectures (like ColdFire or S08) can redirect the vector table, but only to RAM, and not to FLASH. So that’s in my view the reason why you see the vector table redirected to RAM.

LikeLike

Hi Eric

And thank you for a quick reply.

The application notes where for a range of architectures (including coldfire) so your comment makes complete sense out of it. This also complies with the fact that I allready ran my real application from A000 when flashed with a programmer.

What now remain is why I get hard faults in my real app when the blink runs fine. Lets say that the vector table is OK, what else could it be?

Any comment would be of help.

Best regards,

Baldur

LikeLike

it could be that your startup code does not correctly initialize the hardware. For example you need to setup the clock gates/etc otherwise you will run into hard faults. You could attach to your board while running the bootloader/application to see what is going on?

LikeLike

Hi Erich

and thanks for the comments, it really helped me!

I suspected that the bootloader iniatilazed some interrupt generation that the application did not have a service routine for. Carefully looking at vectors.c for both projects I could see that this was not the case, every interrupt used by the bootloader was also used by the applicatio, and as the application starts up, these interrupts must be set right.

Then there could be some setup that happens after BL_CheckForUserApp. In stead of calling my app from BL_Run, I call it from BL_CheckForUserApp and now my application runs. 🙂

Best regards,

Baldur

LikeLike

Hi Erich

Now I can download my application to flash via the bootloader. When I press the reset button on my PCB the application starts fine (when called from BL_CheckForUserApp ). My problem is that in the future I will not have access to the reset button so I would like to start the application from the bootloader (BL_Run, as you do it). But when I call the following(from BL_Run() ), after download of application the bootloader just freeses.

startup = ((uint32_t*)BL_FLASH_VECTOR_TABLE)[1];

if (startup!=-1)

{

((void(*)(void))startup)(); // restart bootloader

}

First of all I do not understand why the bootloader will not work if it reset (as the application has never run and nothing has changed – mabe some interrupt is active, might I have to disable interrupt before restarting?)

Second, is there a programable way to imitate the reset button ( pull reset line low)?

Best regars,

Baldur

LikeLike

Hi Baldur,

BL_Run() does not perform a reset: it only jumps to the startup vector and runs from there. Therefore, no peripherals are reset, so BL_Run() is only a ‘weak’ software restart. What you need is a ‘real’ reset, and to my knowledge without external hardware (which toggles the reset line) the only feasible way is to enable the watchdog: as soon as you do not kick the dog any more, the system will go through a reset.

LikeLike

Hi Erich

Excelent idea with watchdog, I never got to to try it as disabling interrupts in BL_Run() before “soft restart” seems to do what I want:

/* disable all interrupts */

asm(” CPSID i”);

Thank you for all your help! 🙂

Best regards,

Baldur

LikeLike

Thanks Erich! I’ll let you know how it goes!

LikeLike

Hello Erich,

We figured it out!

Clicking reset in CW’s Debug view erases the application’s image in flash. However, pressing the reset button on the freedom board preserves the application’s image.

This is why the problem seemed to be intermittent.

Thanks again for all your help!

LikeLike

Hi Carlos,

this does not make sense to me: pressing the reset button only performs a reset (loading the PC and SP from the vector table), but shall not erase your flash. I believe there must be a different problem

LikeLike

Hi Eric

When in Bootloader project (uses flash up to A000), stopping he debugging session in CW and starting again erases all flash, also the application part (above A000).

LikeLike

Hi Baldur,

can you check what is your ‘erase flash’ condition in your bootloader? I assume it wrongly assumes that condition.

LikeLike

When I run the bootloader in CW debug and download my application I can see the code appear at A000. If I press the reset button in CW (reset the debugger) I see all the code being erased.

I dont know what the ‘erase flash’ condition is.

When closing down the debugger and runing the bootloader code by it self, pressing reset button on my PCB does not erase my application (so this is in real not a problem as this is how it will usually be used (that is bootloader is normally not run out of debugger))

Baldur

LikeLike

Hi Erich

The bootloader is working fine in most computers I have tried, but not in mine. At reset the processor should start in bootloader mode and wait for 10 seconds and then jump to application if available. When switching from bootoader to application most computers give a sound signal (as when USB port is disconnected, I asume that the connection happens so fast that I dont hear that) and I can communicate with the application.

On my PC I dont hear the sound and my terminal program (RealTerm) says “A device attached to the system is not functioning” when I try to open the port, and I can not communicate. There is never a problem communicating with the bootloader immediatley after pulling out and reconnecting the USB connector. I can see that the enumeration in the call to CDC1_App_Task fails.

One idea I had, was that my computer would be slow to detect the disaperance of the port, reconnects to soon again and get confused. I tried to add delays but without luck. I also thought if there was a way to activly disconnect usb, but did not have any luck in finding such functions.

I would be happy for any comment on what the problem could be or where to look.

Best regards,

Baldur

LikeLike

Hi again.

Finally I found some reason. All the ports on my machine is USB3, adding a hub solved the issue 🙂

LikeLike

ah, that makes sense. I avoid USB3 ports whenever possible 😉

LikeLike

Hi Erich,

It works fine on a FRDM-K20D50M after some adjustments.

Thanks a lot.

LikeLike

Hi Bernhard,

great!

LikeLike

About speed to program S19, it takes 5minutes with Terminal.exe, and only 5 seconds with an dedicated application in C#!!

LikeLike

Yes, this because the delay needed for each character is rather large in the terminal program. I tried to get reliable XON/XOFF software handshaking working, but no big success 😦

LikeLike

would you be so kind as to upload your project with FRDM-K20D50M? would be of great help.

Thanks

LikeLike

Hi,

I don’t know if can upload my project here.

LikeLike

You cannot upload it here, but in another public place if possible? Or send it to me by email and I can put it on the McuOnEclipse GitHub, or you can make a pull request on Git too.

LikeLike

My email is : jerryowens@libero.it

If you prefer to make it public send it to Erich.

Thanks

LikeLike

I received the project from Bernard (many thanks!), and I have uploaded it to GitHub here:

https://github.com/ErichStyger/mcuoneclipse/tree/master/Examples

LikeLike

Hello Erich,

I have followed the above procedure to test the bootloader on FRDM-KL25Z. I have downloaded the BL_Blink project as i have no s19 files. I have programmed the bootloader code first. Then through the terminal, I have loaded the s19 file successfully.

If I leave the PTB8 unconnected, Program is always going into bootloader mode. I have connected the 3V3 supply to it, even then also flow is going into bootloader mode only.

What could be wrong with my setup.

Thanks in advance

LikeLike

Hi Durgesh,

the normal configuration is that PTB8 is having a pull-up resistor to 3.3V. The bootloader only goes into bootloader mode if the pin is LOW. If the pin is high, it checks if there is a valid application vector. If so, it enters application mode. Otherwise it remains in bootloader mode. Have you debugged your bootloader code? Then you should see what is going wrong.

LikeLike

Hello Erich,

thanks for this nice job! I have tested under MCF51 (CN128) and works excellent!

Regards,

Juan A Luna

LikeLike

Excellent! Thanks for the confirmation that things work for you that way. I appologize that many times I just test and use things for my own usage, and that this means many times cutting corners too much…

LikeLike

Hi Erich,

I have use your components for FAT filesystem using SDHC (4 data lines) interface in a MK10DN512VLK10. I works really great. But now I need a bootloader for my system using the same interface SD. A few months ago I used AN2295 bootloader for a kl15 cpu and it worked just fine but it does not support SD card interface. You mention before about some possible extension to include SD card support using FAT to read the S19 file. Is this already done or at least I have some code to start from. If you have some comment or hint before I start I will really appreciate it.

Best regards,

William

LikeLike

Hi Erich,

Thank you for this fantastic blog!

I have a FRDM-K64F that use with Kinetis Design Studio and PE now more and more after reading your blog. I got my problem with Freemaster solved!

Although I haven’t tested yet to change from Uart0 that uses the virtual serial port -> Uart2 + using an external USB->wire http://www.ftdichip.com/Support/Documents/DataSheets/Cables/DS_TTL-232R_CABLES.pdf

This is where I run into problem porting your serial bootloader for FRDM-KL25Z to my FRDM-K64F. I haven’t tested all the way to send an s19-file but the help and status command works fine when I use UART0, with RX at PB16 and TX at PB17.

But then when I just change to use Uart2 with RX at PD2 and TX at PD3, there is no communication on this port in the terminal program (on my COM6), but even stranger is that it still works to use the virtual CDC J-link port (on my COM9) where status and help prints ok on this port ????

Can you try to test to change from Uart0 in your project and see if you have this strange behavior also, or does the FRDM-KL25Z only have Uart0?

Kind regards,

Anders

LikeLike

The FRDM-KL25Z has UART0, UART1 and UART2. I used UART0 on the FRDM-KL25Z because this is the one connected to the OpenSDA so I have a virtual COM port on the PC. Same on the FRDM-K64F board: the UART0 is connected to the OpenSDA. Everything sent to the UART0 will end up on the K20, so if you are using the J-LINK firmware, then you will get it there. If you send things to UART2, then you should not get anything on UART0 (at least I have not seen that on my side). I believe you made a change, but you are still downloading the previous program? Have you regenerated code and compiled it again?

LikeLike

Yes you are right it is the old serial bootloader on Uart0 that is still running. Now I created a smaller test-program that just sends on Uart2 without anything else but I still see the red led blink and the debuggger is strange and doesn’t stop at main etc, so I looked at the GDB printouts in the console window and this line:

ERROR: Failed to erase sectors 0 @ address 0x00000000 (Algo135: Flash protection violation. Flash is write-protected.)

explains why 🙂

How do I erase this protected flash?

/Anders

LikeLike

Hi Anders,

The easiest option is to use the P&E (not the Segger) firmware. The P&E OpenSDA firmware always does a mass erase, while the J-Link does not. I see if I can find and post a solution for J-Link. Until then, use the P&E firmware.

LikeLike

I found J-Link commander and managed to unlock 🙂

/Anders

LikeLike

which command(s) did you use? I tried ‘erase’ and this did not work for me.

LikeLike

Guess I have answered now my own question 🙂 with https://mcuoneclipse.com/2014/10/05/unlocking-and-erasing-flash-with-segger-j-link/

It looks like I need to set the device first, then unlock followed by an erase.

LikeLike

Pingback: Unlocking and Erasing FLASH with Segger J-Link | MCU on Eclipse

Hi Erich!

I have problem with this serial bootloader that I have “ported” to FRDM-K64F

It seems that it flashes everything ok, but then when I run the code, I get a hardfault in __copy_rom_to_ram it reads from 0x20c314 where there are no ROM

I have tested to dowload both the BL + my testApp with the debugger and then it works ok and reads from 0xc314

To verify the complete s19 file to what has been flashed it seems it should be possible with J-link commander, you can use “savebin” and veryfybin and even loadfile that takes a s19 file als.

But I dont trust the verify command, as it already complains at the first address and says it is not zero that it should be, but with the debugger I can see that it is zero.

Do you have any other tool or Idea to use to compare what has been flashed to the complete s19 file?

LikeLike

it seems to me that maybe the code is wrong if you say it crashes for 0x20c314 but works for 0xc314?

Or is it a problem with resetting the processor and registers are not cleared properly? Does it happen if you do a ‘soft’ reset or a ‘hard’ reset (with the reset pin) too?

LikeLike

Sorry for not beeing clear, the bl + the app works perfectly if I download them via the debug interface from within KDS, but if I just download the BL and run it and download the app as an S19 file in the terminal program it takes quite a while BL is from 0-0x8000 and the test app is from 0x8000-0xC320 and the BL writes Done! And the red led starts blink again.

But after a reset the app doesn’t work. When I debug with just loading the symbols I singels step to just before I get the hard fault and it is because it tries to copy data from flash to ram but at 0x20C314 there are no memory at all.

If I instead debug to the same place with the app downloaded via gdb both symbols and executable it copies from the correct address 0xC314, and it runs perfectly after.

So my conclusion is that the flashed s19 is downloaded incorrectly. Either it is not correct generated or the BL doesn’t flash it correctly, do you follow me so far?

So here comes my question of best method or tool to read out a memory “dump” and first comparing this dump of the app that has been downloaded via gdb and works ok

And somehow compare it to the s19 file to be sure that the s19 is correctly generated

Than download via serial boot loader and compare the area 0x8000-0xC320 to the s19 file or an stored bin file of the same area but flashed via gdb.

As this readout and comparing tool I tested to use the J-link commander with its verifybin and savebin commands but I don’t trust the verifybin because it stated that it expected a zero byte at start address but it was something else, but when I debuged via gdb downloading just symbols and NOT the executable code I could see in memmory watch window at this address it was zero.

Any help on method or tools to compare memory to s19 file or bin file is much appreciated.

Anders

LikeLike

Hi Erich

I have found a bug:

My test app:

C:\Tools\srecord-1.64-win32>srec_info Test4.s19

Format: Motorola S-Record

Header: “Test4.s19”

Execution Start Address: 000089A1

Data: 8000 – 8197

8410 – C33F

and the last lines in this Test4.s19 are:

S10FC300F8B500BFF8BC08BC9E467047AE

S107C30C8584000020

S107C3105984000048

S10BC3140100000064000000B8

S113C31C14C3000000000020080000001CC300002F

S113C32C0000FF1F000000000000000000000000DF

S107C33C00000000F9

S90389A1D2

Note all other lines above these are all the same with 0x10 number of actual data (that is they start with S113)

After flashing this Test4.s19 via the “BL load s19” in the terminal

I use J-Link commander

and I try to read the memory at 0xC300

device mk64fn1m0xxx12

J-Link>mem 0xc300 0x40

Could not read memory.

After erasing and unlocking and downloading the serial bootloader again

and sending a modified Test_ver2.s19

where I hand modified the last lines so they are all 0x10 number of data;

S113C300F8B500BFF8BC08BC9E46704785840000A1

S113C31059840000010000006400000014C3000000

S113C32000000020080000001CC300000000FF1FE4

S113C33000000000000000000000000000000000F9

S90389A1D2

Then it works and I can read the data with the mem command + the application runs perfectly, it is a Freemaster Demo app that comes with the serial device driver ver 1.8.1 from Freescale

At 0xC300 is the copy from ROM to Ram init values that explain why I had the strange hardfault

Have you tested to flash with these kind of s19 file that doesn’t have a fixed 0x10 number of data all the lines, especially in the end?

Or do you think it is some difference in some “lash write number of bytes” parameter between K64F and your KL25Z?

/Anders

LikeLike

Hi Anders,

what is the ‘S19 Buffer Size’ setting of your S19 component?

Can you check S19_BUF_NOF_BYTES?

Erich

LikeLike

Hi Erich,

#define S19_BUF_NOF_BYTES 252 /* size in code bytes for the longest S19 line we expect */

No line is so long, the longest are the ones with 0x10 data bytes that start with “S113” and these seems to work ok.

Have you tested on your board to download these last lines, that i have problem with?

I will test to see if I can repeat the problem also with only these last lines in a very short s19 file.

Anders

LikeLike

I have tried on my KL25Z board your lines:

S00F0000424C5F426C696E6B2E686578A0

S10FC300F8B500BFF8BC08BC9E467047AE

S107C30C8584000020

S107C3105984000048

S10BC3140100000064000000B8

S113C31C14C3000000000020080000001CC300002F

S113C32C0000FF1F000000000000000000000000DF

S107C33C00000000F9

S90389A1D2

in a S19 files (just the above lines). And I checked the memory, and they get programmed correctly.

Can you check with the debugger/memory view, and that looks good.

LikeLike

Yes it doesn’t only have todo with these last lines, because they work also ok on my board, can I send you my complete s19 file somehow?

Kind regards

Anders

LikeLike

Yes, you can send it to my email address mentioned on the About page of this blog. I just might not have much time the next days or so.

LikeLike

Did you solve your problem? Because I work on it too.

I’ve already “ported” this bootloader on the K20 and that was easier 🙂 Now I have to work with the K64 and there are littles differences which stop me.

For this moment I can start with the bootloader and I have no error when I send the s19 file in the K64.

But my problem is to launch the application. I can’t left the BL mode.

I thnik its due to the start process. Indeed I can’t find the “User initialization” property in the build options. So I’ve tried to put BL_CheckForUserApp just after the PE_low_level_init but it does not seem the right thing to do..

When (and where) can I check if I have to go in the BL or in the application?

Regards,

Anthony.

LikeLike

Anthony,